production of daily wines or customized packaging of high-end premium wines, a scientific selection method can avoid procurement risks and reduce unnecessary costs. Today, we will share professional tips on purchasing glass wine bottles, combining industry norms and practical application scenarios to help you make informed decisions.

1. Development Trend of Glass Wine Bottles: The First Choice for Wine Packaging

Glass wine bottles have always been the mainstream packaging for alcoholic beverages, and this status is determined by their unique advantages: stable chemical properties, no reaction with wine, good sealing performance, and the ability to preserve the flavor and quality of wine for a long time.

In the current market, glass bottles are widely used for packaging medicines, health products, various foods, beverages, and especially wines. When you drink wine, you will find that most wines use glass wine bottles—except for a very small number of beers packaged in plastic bottles. With the increasing demand for high-quality wine and the emphasis on environmental protection, glass wine bottles are also developing in the direction of lightweight, high strength, and personalized design, which not only reduces transportation costs but also meets the diversified packaging needs of wineries.

2. Core Standards for Selecting Glass Wine Bottles

Selecting high-quality glass wine bottles requires comprehensive consideration of bottle material, sealing performance, product quality standards, and manufacturer’s strength. The specific standards are as follows:

2.1 Choose the Right Bottle Material and Color According to the Wine Type

Glass wine bottles are divided into different grades and colors according to the raw material formula and production process, and different wines need to be matched with corresponding bottle types:

- Classification by material grade:

- High-white glass bottles: High transparency, pure color, no impurities, suitable for packaging high-end white wine, white wine, and sparkling wine. The crystal-clear appearance can highlight the purity of the wine and enhance the product’s premium sense.

- Crystal-white glass bottles: Higher refractive index than high-white glass, with a crystal-like luster, suitable for luxury gift wine packaging, such as high-end brandy and whiskey.

- Ordinary-white glass bottles: Moderate transparency and cost-effective, suitable for bulk packaging of daily wines, which can reduce procurement costs under the premise of ensuring basic quality.

- Classification by color:

- Opaque milk-white bottles: The surface is smooth and white, with a high-end and elegant appearance, suitable for packaging characteristic wines. For example, Maotai mostly uses milk-white glass bottles, which have become a unique symbol of its brand.

- Colored bottles (dark brown, dark green, etc.): Strong light-blocking ability, which can effectively block ultraviolet rays and prevent wine from being oxidized and deteriorated due to light exposure. They are specially used for packaging red wine, as red wine is sensitive to light and needs long-term storage protection.

- Transparent bottles: Can directly display the color of the wine, suitable for packaging high-degree white wine, white wine, and other wines with clear and transparent liquid, which is convenient for consumers to observe the quality of the wine.

2.2 Focus on the Sealing Performance of the Bottle Body and Cap

The sealing performance of glass wine bottles directly determines the storage life of the wine—poor sealing will lead to alcohol volatilization, oxidation of the wine, and bacterial contamination, which will seriously affect the quality of the wine. The key to ensuring sealing performance lies in the gasket of the bottle cap:

- The gasket is located between the bottle cap and the mouth of the glass wine bottle, and its main function is to fill the gap between the cap and the bottle mouth to achieve airtight and leak-proof effects.

- When purchasing, you should check the material of the gasket—food-grade silicone gaskets and cork gaskets are the best choices, as they have good elasticity, corrosion resistance, and no harmful substance leaching, which can adapt to different storage environments (temperature changes, humidity changes) and maintain stable sealing performance.

- In addition, you should also test the matching degree between the bottle cap and the bottle mouth: the cap should be tightly fitted, not loose or easy to fall off, and there should be no leakage when the bottle is inverted.

2.3 Check the Manufacturer’s Product Quality Standards

Product quality standards are the core basis for judging the quality of glass wine bottles. When purchasing, you should require the manufacturer to provide detailed product execution standards, which can help you analyze the quality of the products in depth:

- Check whether the product meets national food safety standards (such as GB 4806.5-2016 Food Safety National Standard for Glass Containers), which is the basic threshold for ensuring that the glass bottles are non-toxic and harmless.

- Focus on key quality indicators, such as wall thickness uniformity, impact resistance, and heavy metal leaching limit. High-quality glass wine bottles have uniform wall thickness (error ≤ ±0.1mm), can pass the 1.2m drop test without cracking, and the leaching amount of heavy metals such as lead and cadmium is far lower than the national limit.

- For wineries exporting to the EU, North America, and other markets, it is also necessary to check whether the products have passed international certifications such as SGS and LFGB to ensure compliance with the import standards of the target market.

2.4 Evaluate the Manufacturer’s Quality Assurance System

Auditing the manufacturer’s quality assurance system has become an indispensable key step in purchasing glass wine bottles. A reliable manufacturer should have a complete quality management system, which can be evaluated from the following aspects:

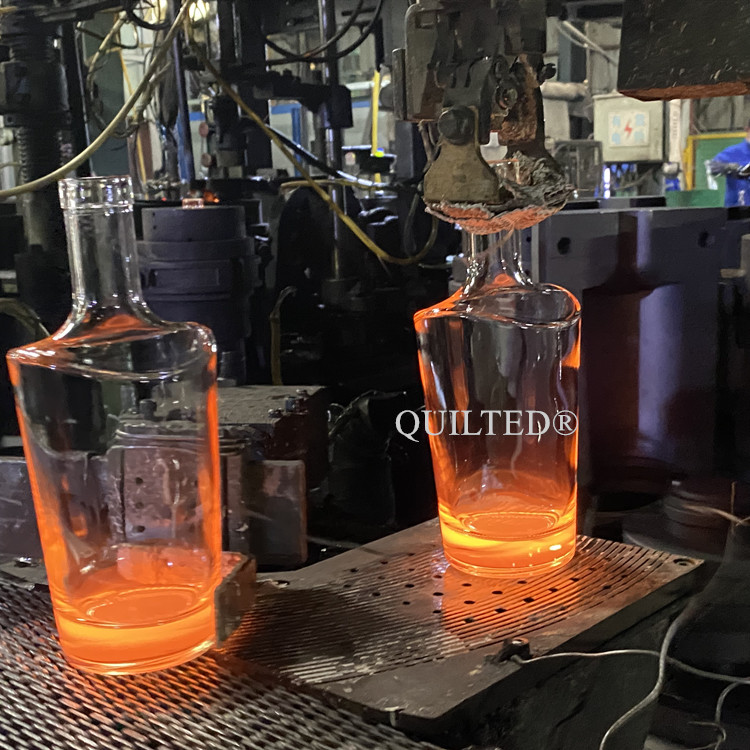

- Hardware facilities: Check whether the manufacturer has advanced automated production lines, precision molds, and professional testing equipment (such as polarized light stress testers, heavy metal leaching detectors). Advanced equipment is the basis for ensuring stable product quality and large-batch supply capacity.

- Software strength: Understand the manufacturer’s technical team, production management system, and after-sales service system. A manufacturer with a professional technical team can provide customized bottle design services, and a sound after-sales service system can solve problems such as product defects and delayed delivery in a timely manner.

- On-site audit: If conditions permit, you can conduct an on-site audit of the manufacturer’s factory to check the production environment, raw material storage, quality inspection process, and other links, so as to make a comprehensive and accurate evaluation of the manufacturer’s overall strength.

3. Additional Tips for Purchasing Glass Wine Bottles

- Sample testing first: Before placing a large batch order, you should request the manufacturer to provide sample bottles for testing, including sealing performance test, impact resistance test, and heavy metal leaching test, to ensure that the samples meet your quality requirements.

- Consider customized needs: If you need to highlight your brand characteristics, you can choose a manufacturer that supports customized services, such as embossing the brand logo on the bottle body, customizing special bottle shapes, and matching unique bottle caps.

- Control the procurement cost reasonably: On the premise of ensuring quality, you can choose the right bottle grade according to the positioning of your wine products. For example, daily wines can choose ordinary-white glass bottles to reduce costs, while high-end gift wines can choose high-white or crystal-white glass bottles to enhance the brand image.

In conclusion, purchasing glass wine bottles is not a simple transaction, but a systematic work that combines product positioning, quality inspection, and manufacturer evaluation. By following the above standards and tips, wineries can select high-quality, cost-effective glass wine bottles that meet their own needs and lay a solid foundation for the sales of wine products.

Post time: Dec-23-2025