For wineries purchasing glass bottles in bulk, the forming method of glass bottles is not just a production technicality—it directly determines the consistency of bottle shape, wall thickness uniformity, pressure resistance, and even the long-term storage safety of wine. As a professional glass bottle manufacturer with SGS and LFGB certifications, we have mastered a full set of automated forming technologies tailored for wine bottle production, ensuring that every batch of bulk orders meets the strict quality standards of wineries. Today, we will systematically interpret the evolution of glass bottle forming methods, focus on the core processes suitable for wine bottle production, and reveal how advanced forming technologies guarantee the quality of bulk wine bottle supplies.

1. The Evolution of Glass Bottle Forming: From Manual Craftsmanship to Automated Mass Production

The history of glass bottle forming spans over 300 years, and its development is closely linked to the demand for industrialization and standardization:

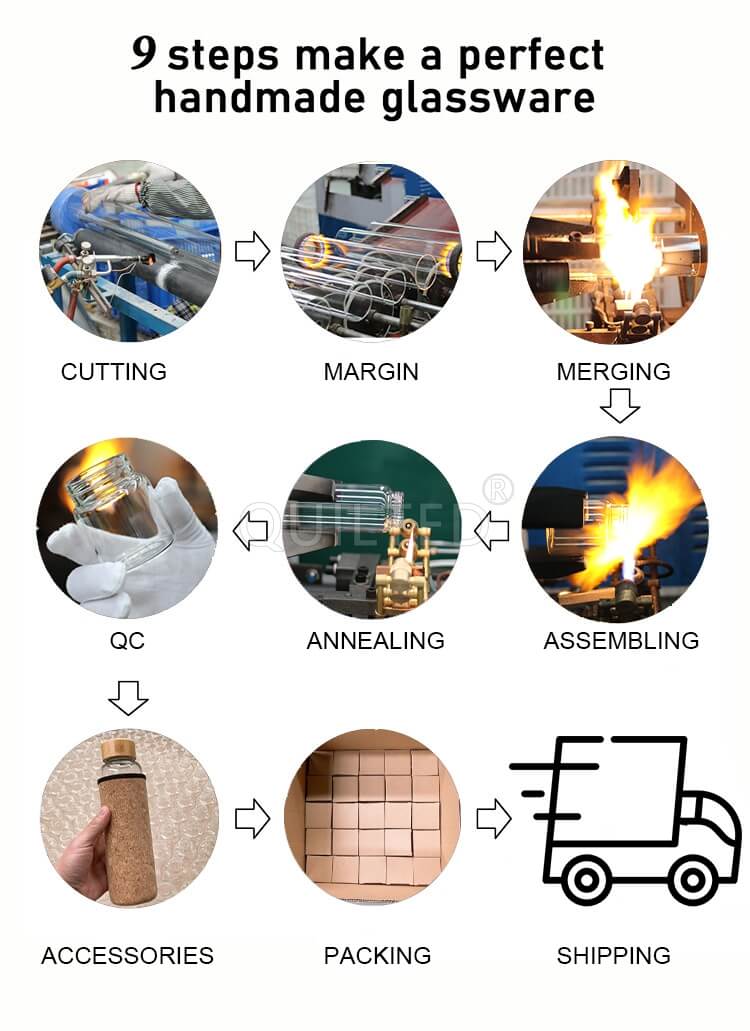

Manual forming (300 years ago to the early 20th century): In the early days, glass bottle forming relied entirely on the skills of craftsmen. Workers would take molten glass with a blowpipe, blow it into a rough shape, and then mold it manually with tools. This method was characterized by low efficiency, high labor costs, and large differences between individual products—it was only suitable for small-batch production of artistic glassware or customized bottles, and completely unable to meet the bulk procurement needs of wineries.

Semi-automatic forming (mid-20th century): With the emergence of simple mechanical equipment, part of the manual operation was replaced by machines—for example, using molds to fix the bottle shape and manual blowing to control the thickness. Although the efficiency was improved compared with manual forming, the problem of inconsistent product quality still existed, and it was difficult to adapt to the large-scale production of standardized wine bottles.

Full-automatic mechanical forming (late 20th century to the present): This is the core forming method adopted by modern glass bottle factories serving bulk winery customers. By integrating high-precision CNC equipment, intelligent temperature control systems, and automated transmission lines, the entire process from molten glass feeding to bottle forming and annealing is completed by machines. This method not only achieves a daily output of 600,000+ bottles, meeting the large-volume demand of wineries, but also ensures that the dimensional error of each bottle is controlled within ±0.1mm, solving the pain point of uneven bottle quality in bulk procurement.

It is worth noting that manual or semi-automatic forming is still retained in the industry, but it is only used for the production of small-batch, high-value-added products such as gift glassware, art lighting glass, and customized creative bottles. For wineries that need stable bulk supply of standard wine bottles, full-automatic mechanical forming is the only reliable choice.

2. Core Forming Methods of Wine Bottles: Blow-Blow & Press-Blow Processes

Glass products have diverse forming methods due to differences in shape, weight, wall thickness, and glass composition—common methods include pressing, blowing, drawing, float glass, wire drawing, and pouring. Among them, the two core processes most suitable for wine bottle production are blow-blow forming and press-blow forming. These two methods fully utilize the characteristic of glass—its viscosity increases rapidly as temperature decreases: molten glass flows freely at high temperatures, gradually hardens into a viscoelastic state as temperature drops, and finally solidifies into a fixed shape. In addition, factors such as glass crystallization tendency, surface stress, and thermal conductivity are precisely controlled during the forming process to avoid defects such as cracks and bubbles.

(1) Blow-Blow Forming: The Optimal Choice for Small-Mouth Wine Bottles

Blow-blow forming is the most widely used process for standard wine bottles (such as 750ml red wine bottles, 375ml white wine bottles) with small mouths and thick walls. Its process flow is highly automated and suitable for large-scale bulk production:

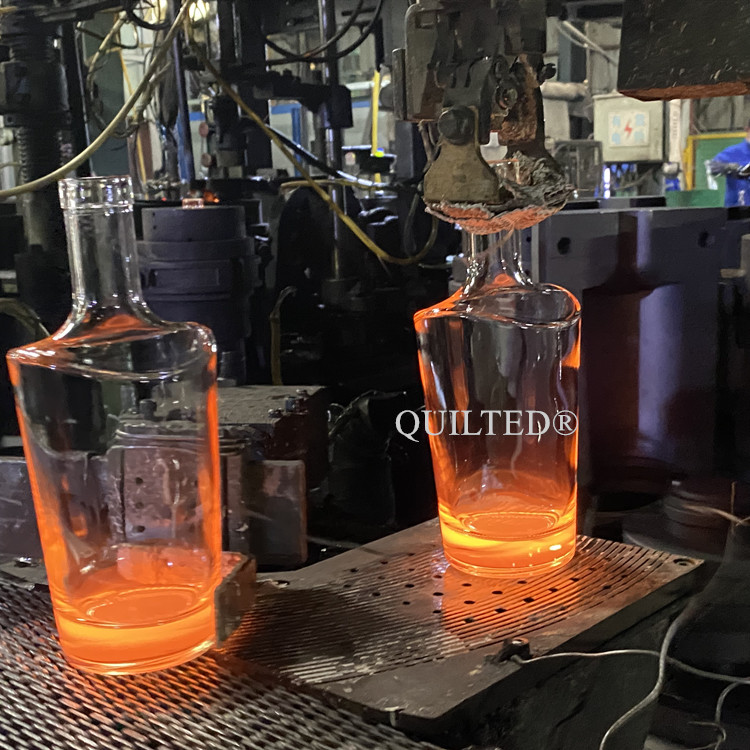

Molten glass cutting: High-temperature molten glass (about 1100℃) is cut into fixed-weight glass gobs by a mechanical shear—for 750ml wine bottles, the weight of each glass gob is precisely controlled at 450-480g to ensure uniform wall thickness of the finished bottle.

Initial mold blowing (parison forming): The glass gob falls into the initial mold, and compressed air is blown into it to form a hollow parison with a neck. At this stage, the neck size of the bottle is fixed, which is crucial for the subsequent wine filling line matching of wineries.

Transfer to forming mold: The parison is transferred to the forming mold by a mechanical arm. At this time, the temperature of the glass drops to 850-900℃, and it enters a viscoelastic state—neither too fluid nor too hard, which is the best forming temperature.

Final blowing and shaping: Compressed air is blown into the parison again, and the glass is attached to the inner wall of the forming mold under air pressure, forming the final shape of the wine bottle (including bottle body, shoulder, bottom).

Annealing and cooling: The formed bottle is immediately sent to the annealing furnace for slow cooling to eliminate internal stress, which is the key step to prevent the bottle from cracking during storage and transportation.

The biggest advantage of blow-blow forming is that it can produce small-mouth bottles with uniform wall thickness and strong pressure resistance—our blow-blow formed wine bottles can withstand an internal pressure of 1.2MPa, fully meeting the storage requirements of sparkling wine with high carbon dioxide content. This process is suitable for bulk orders of 100,000+ bottles, with a qualified rate of over 99.5%.

(2) Press-Blow Forming: The Ideal Solution for Large-Mouth & Thick-Bottom Wine Bottles

Press-blow forming is mainly used for the production of special wine bottles such as large-mouth brandy bottles, thick-bottom whiskey bottles, and customized magnum bottles (1.5L/3L). Compared with blow-blow forming, it adds a “pressing” step, which is more suitable for bottles with complex shapes and thick local walls:

Glass gob feeding and pressing: The glass gob falls into the mold, and a metal plunger is pressed down from the top to squeeze the glass into the shape of the parison—this step can precisely control the thickness of the bottle bottom (up to 8-10mm), enhancing the stability of the bottle and preventing it from toppling over on the winery shelf.

Blowing and shaping: After the plunger is lifted, compressed air is blown into the parison to make the glass fit the mold and form the complete bottle shape.

Demolding and annealing: The process is the same as blow-blow forming, but the annealing time is extended by 1-2 hours for thick-bottom bottles to ensure the elimination of internal stress in the thick glass part.

Press-blow forming is characterized by strong adaptability to complex bottle shapes—we have used this process to customize thick-bottom whiskey bottles for a Scottish distillery, and the finished bottles not only have a high-end appearance but also pass the 1.5-meter drop test without cracking, fully meeting the bulk packaging needs of high-end liquor brands.

3. Other Common Glass Forming Methods (Not Suitable for Wine Bottle Bulk Production)

In addition to blow-blow and press-blow forming, there are other forming methods in the glass industry, but they are not suitable for wine bottle production due to process characteristics:

Float glass forming: Mainly used for producing flat glass such as window glass and photovoltaic glass. The molten glass floats on the surface of molten tin to form a flat sheet, which cannot be used to make hollow bottle products.

Drawing forming: Suitable for producing long strip glass products such as glass tubes and optical fibers. It relies on mechanical traction to stretch the molten glass into a strip shape, which is not applicable to the three-dimensional shape of wine bottles.

Pouring forming: Pouring molten glass into molds and letting it cool and solidify naturally. This method has low efficiency and poor dimensional accuracy, and is only used for small-batch production of artistic glassware.

4. How Our Forming Technology Guarantees the Quality of Bulk Wine Bottle Orders

For wineries, the core demands for bulk glass bottle procurement are stable quality, consistent specifications, and on-time delivery. Our advanced forming technology and strict process control perfectly meet these demands:

Intelligent temperature control: The temperature of molten glass is controlled within ±5℃ by an automatic temperature control system during the forming process, ensuring that the viscosity of the glass is stable and avoiding defects such as uneven wall thickness caused by temperature fluctuations.

Mold precision management: All forming molds are made of high-temperature resistant alloy steel, with a machining accuracy of ±0.05mm. For bulk orders, we use dedicated molds to avoid cross-contamination of different bottle types and ensure consistent product specifications.

Full-process quality inspection: After forming, each bottle is inspected by an automated visual detection system for defects such as cracks, bubbles, and uneven necks. Defective products are automatically removed, and the qualified rate of finished products is maintained at over 99.5%.

Efficient bulk production capacity: Equipped with 8 full-automatic blow-blow and press-blow production lines, we can complete the production of 1 million standard wine bottles within 15 days, ensuring that wineries’ production schedules are not delayed.

In addition, all bottles produced by our forming processes have passed SGS and LFGB certifications—the uniform wall thickness and stable structure ensure that there is no risk of harmful substance leaching, providing a double guarantee for the safety of winery products.

If you are a winery looking for a bulk glass bottle supplier with advanced forming technology and reliable quality, please contact us. We can provide customized forming solutions according to your bottle shape requirements, and offer free sample testing to verify the pressure resistance and quality consistency of the bottles.

Post time: Dec-29-2025