For wineries purchasing glass bottles in bulk, the quality of glass bottles directly determines the safety of wine storage, the stability of product quality, and even the brand image. A low-quality glass bottle may crack during transportation, leak wine due to uneven wall thickness, or even leach harmful substances, causing huge economic losses to wineries. As a professional glass bottle manufacturer with SGS and LFGB certifications, we have accumulated rich experience in bulk production of wine bottles. Today, we will deeply analyze the core factors affecting the quality of glass bottles, helping you accurately judge the quality of products during bulk procurement and avoid potential risks.

1. Manufacturer’s Technical Strength: The Core Guarantee of Bulk Quality Stability

The technical strength of glass bottle manufacturers is the “hard power” that determines the quality of bulk products. For wineries, choosing a manufacturer with advanced production technology, mature management model and good industry reputation is the first step to ensure the quality of glass bottles. Specifically, technical strength is reflected in three aspects:

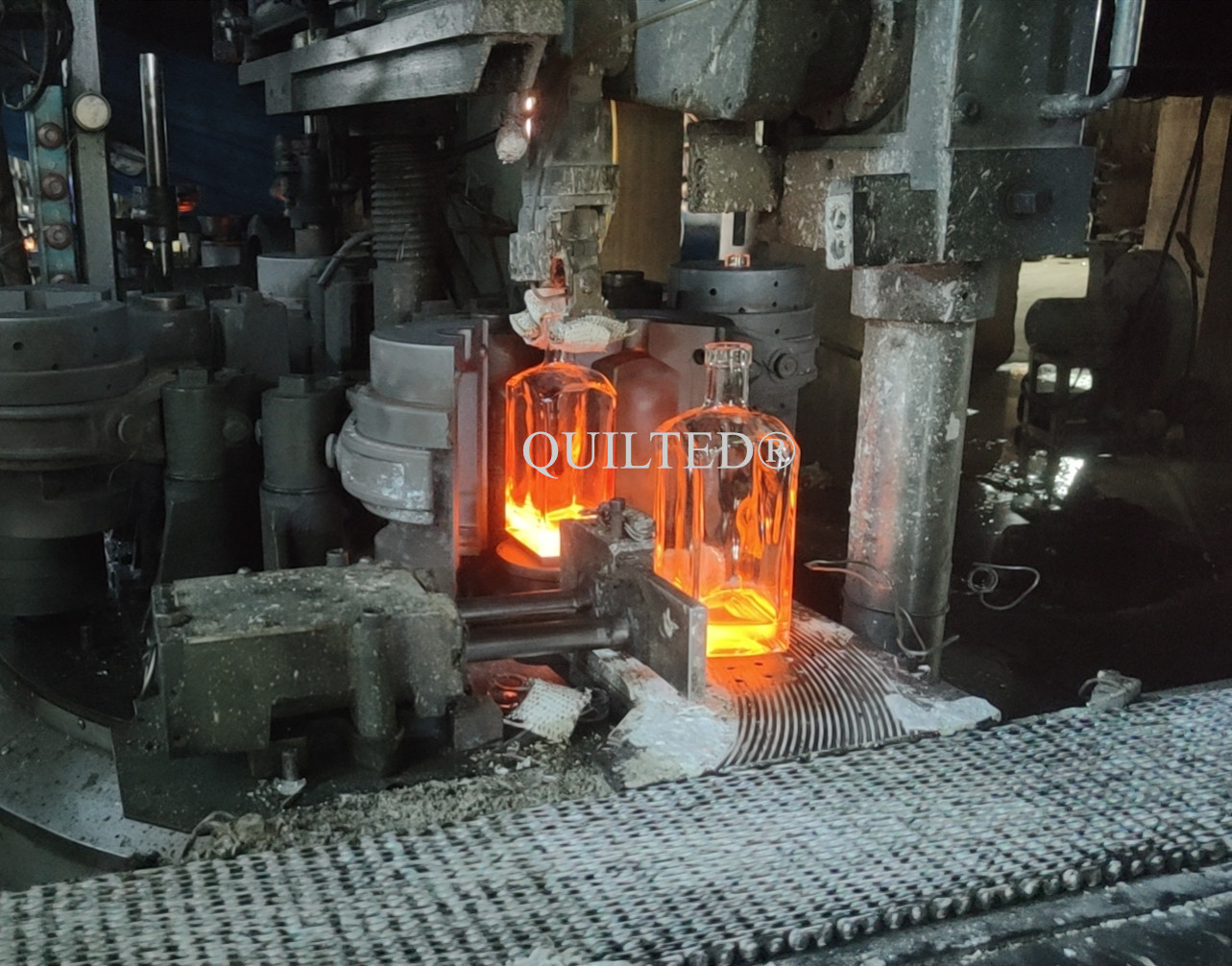

Advanced production equipment: Modern full-automatic production lines (such as imported German CNC forming equipment) can accurately control every link of glass bottle production, from the weight of glass gobs (error ≤±5g) to the uniformity of wall thickness (tolerance ≤±0.1mm). Compared with small manufacturers using outdated semi-automatic equipment, the qualified rate of products produced by advanced equipment is as high as 99.5% or more, which can avoid the problem of uneven quality in bulk orders.

Mature process system: Professional manufacturers have a complete set of process standards for wine bottle production, including raw material proportioning, melting temperature control (1580℃ constant temperature), forming pressure adjustment, etc. Taking our factory as an example, we have formulated targeted process parameters for different types of wine bottles (such as red wine bottles, sparkling wine bottles, brandy bottles). For example, the forming pressure of sparkling wine bottles is increased by 20% to enhance their pressure resistance, ensuring that they can withstand the internal pressure of carbon dioxide during wine storage.

Strict quality management system: Advanced manufacturers have established a full-process quality control system from raw material inspection to finished product delivery. Each batch of products must pass multiple tests such as heavy metal leaching, pressure resistance, and impact resistance before leaving the factory. Our factory has passed ISO9001 quality management system certification, and all wine bottle products have obtained SGS and LFGB certifications, which is a strong proof of product quality.

It should be emphasized that for wineries purchasing in bulk, the technical strength of manufacturers directly affects the delivery efficiency. Our factory with 8 full-automatic production lines can complete the production and delivery of 1 million standard wine bottles within 15 days, ensuring that wineries’ production schedules are not delayed.

2. Glass Mold Quality: The “Blueprint” Determining Bottle Shape and Precision

The design and manufacturing quality of glass molds is a key factor affecting the appearance and dimensional accuracy of glass bottles. A high-quality mold can minimize production errors, while a defective mold will not only fail to meet the needs of wineries but also cause waste of resources and costs. For bulk procurement of wineries, the impact of mold quality is mainly reflected in the following aspects:

2.1 Dimensional accuracy of the mold

The mold is the “template” of glass bottles. The accuracy of its internal structure directly determines the size of the bottle (such as height, diameter, neck size). If the mold has dimensional errors, it will lead to inconsistent sizes of glass bottles in the same batch. For wineries, this will cause problems such as difficulty in matching the filling line and uneven stacking during storage. Our factory uses high-temperature resistant alloy steel to make molds, and the machining accuracy is controlled within ±0.05mm. For bulk orders, we will use dedicated molds to avoid cross-contamination of different bottle types and ensure that the dimensional consistency of each bottle meets the requirements of wineries.

2.2 Mold surface quality

The surface finish of the mold directly affects the surface smoothness of glass bottles. If the mold surface is rough or has burrs, the produced glass bottles will have surface defects such as scratches and unevenness, which will affect the appearance of the product and the consumer’s purchase desire. In addition, a smooth mold surface can reduce the friction between the glass and the mold during the forming process, avoiding defects such as bubbles and cracks caused by excessive resistance. Our factory’s molds will go through multiple processes such as grinding and polishing, and the surface roughness is ≤Ra0.8μm, ensuring that the produced glass bottles have a smooth and transparent surface.

2.3 Mold service life and maintenance

For bulk production, the service life of the mold is also an important factor affecting product quality stability. A high-quality mold can withstand the erosion of high-temperature molten glass (about 1100℃) for a long time, and the product quality will not decrease after producing 100,000+ bottles. Our factory has a professional mold maintenance team that regularly inspects and maintains the molds, including cleaning the mold surface, repairing wear parts, etc., to ensure that the molds are always in the best working condition.

3. Annealing Process: In-Depth Technical Analysis & Customization for Different Wine Types

After the glass bottle is formed, it will go through drastic changes in temperature and shape—from 1100℃ molten glass to room-temperature solid bottle. This rapid temperature drop causes uneven thermal expansion and contraction inside the glass, resulting in “internal stress”. If the internal stress is not eliminated, the glass bottle will be prone to cracking during storage (e.g., temperature changes in the warehouse), transportation (e.g., collision and vibration), or use (e.g., filling with warm wine). The annealing process is the core step to solve this problem, and its technical details directly determine the mechanical strength and service life of the glass bottle.

3.1 Core Principles & Key Technical Parameters of Annealing

The essence of annealing is to “reheat the formed glass bottle to the ‘annealing temperature range’ (520-600℃ for soda-lime glass, which is the temperature range where glass internal stress can be relaxed) and then cool it slowly”. The key lies in two parameters: annealing temperature and cooling rate.

Annealing temperature: Too low a temperature cannot fully relax the internal stress; too high a temperature will cause the glass bottle to deform. Our factory uses an intelligent temperature control system with a precision of ±3℃ to lock the annealing temperature according to the bottle thickness. For standard 750ml red wine bottles (wall thickness 2.8-3.2mm), the annealing temperature is set at 560℃; for thick-bottom whiskey bottles (bottom thickness 8-10mm), the temperature is increased to 580℃ to ensure that the thick glass part can fully release stress.

Cooling rate: The cooling rate in the annealing temperature range is the most critical. If cooled too fast, the internal stress will reappear; if cooled too slow, production efficiency will be reduced. We adopt a “segmented cooling” strategy: first, cool from the annealing temperature to 400℃ at a rate of 5℃/min (the stress relaxation stage); then cool from 400℃ to 200℃ at a rate of 10℃/min; finally, cool to room temperature at a rate of 15℃/min. This balance between stress elimination and production efficiency ensures that the internal stress of the finished bottle is ≤5MPa (far below the industry limit of 12MPa).

3.2 Annealing Quality Testing: How to Verify the Effect?

For wineries purchasing in bulk, it is crucial to verify the annealing quality of glass bottles. Our factory uses two professional testing methods to ensure that every batch of products meets the standard:

Polarized light stress test: Put the glass bottle into a polarized light tester—if there are obvious bright and dark stripes, it means there is residual internal stress. Our qualified products have no obvious stress stripes, and the stress distribution is uniform.

Thermal shock test: Simulate the extreme temperature change scenario of wineries (e.g., from -10℃ cold storage to 40℃ transportation). The bottle is soaked in -10℃ refrigerant for 2 hours, then immediately transferred to 40℃ warm water for 2 hours. Qualified bottles (after annealing) will not crack or leak, which is a key guarantee for wineries exporting to regions with large temperature differences (such as Northern Europe and North America).

Taking our factory as an example, we have developed customized annealing processes for different wine types based on their storage and use characteristics:

| Wine Type | Key Quality Requirements for Glass Bottles | Customized Annealing Scheme | Quality Guarantee Effect |

| Red Wine (Long-term Aging, 2-5 Years) | High pressure resistance (to withstand slight fermentation gas), strong thermal stability (to adapt to warehouse temperature changes) | Annealing temperature 560℃, holding time 5 hours, slow cooling rate (5℃/min in the stress relaxation stage) | Internal stress ≤4MPa, thermal shock resistance ±50℃, no cracking during 5-year storage |

| White Wine/Rosé Wine (Short-term Fresh Storage, ≤1 Year) | Lightweight (to reduce transportation costs), good transparency (to show the color of the wine), moderate impact resistance | Annealing temperature 550℃, holding time 4 hours, slightly faster cooling rate (8℃/min in the stress relaxation stage) | Internal stress ≤6MPa, weight reduced by 10% compared with red wine bottles, impact resistance meets 1.2m drop test |

| Sparkling Wine/Champagne (High Internal Pressure, 0.8-1.2MPa) | Ultra-high pressure resistance, uniform wall thickness, no residual stress (to avoid explosion due to pressure) | Annealing temperature 570℃, holding time 6 hours, ultra-slow cooling rate (3℃/min in the stress relaxation stage), additional secondary annealing for the bottle shoulder (stress concentration area) | Can withstand internal pressure up to 1.5MPa (exceeding the standard of 1.2MPa), explosion rate ≤0.01% in bulk storage |

| High-Alcohol Liquor (Brandy/Whiskey, Thick Bottle Bottom) | Thick bottom (to enhance stability), strong scratch resistance, no taste migration | Annealing temperature 580℃, holding time 7 hours, targeted heat preservation for the bottle bottom (extending the holding time by 2 hours) | Bottle bottom stress completely eliminated, no deformation after long-term stacking (8 layers), no heavy metal leaching in high-alcohol environment |

Note: Poor annealing is one of the main reasons for the high cracking rate of glass bottles in bulk procurement. When wineries purchase in bulk, they can ask manufacturers to provide annealing process parameters and thermal shock test reports to verify the quality of annealing. For special wine types (e.g., low-temperature stored ice wine), we can also customize the annealing process to meet personalized quality requirements.

4. Operator Skills: The “Human Factor” Guaranteeing Production Quality

Although modern glass bottle production is highly automated, the skills and sense of responsibility of operators still play an important role in product quality. Especially in the links of raw material proportioning, mold installation, and quality inspection, the operation level of workers directly affects the quality of the final product.

A professional glass bottle manufacturer will conduct systematic training for operators, including equipment operation, process parameters control, quality defect identification, etc. Our factory’s operators have more than 3 years of relevant work experience on average, and must pass strict skill assessments before taking up their posts. In the production process, operators will regularly inspect the semi-finished and finished products, and immediately adjust the process parameters if any defects are found. For example, in the raw material proportioning link, workers will accurately weigh each raw material according to the formula to ensure that the glass composition meets the standard, avoiding the problem of low strength of glass bottles caused by incorrect proportioning.

5. How to Judge the Quality of Glass Bottles for Different Wine Types During Bulk Procurement?

Based on the above factors affecting quality and the customized requirements of different wine types, wineries can judge the quality of glass bottles from the following targeted aspects during bulk procurement:

Check the manufacturer’s qualifications and customized capabilities: Ask for relevant certifications such as SGS, LFGB, and ISO9001; focus on understanding whether the manufacturer can provide customized annealing processes and mold designs for your wine type (e.g., whether there is experience in producing high-pressure resistant bottles for sparkling wine).

Targeted sample inspection:

For red wine (long-term aging): Check the wall thickness uniformity (use a caliper to measure, error ≤±0.1mm) and conduct a thermal shock test (simulate warehouse temperature changes);

For sparkling wine: Request a pressure resistance test report (must withstand ≥1.2MPa) and check the bottle shoulder thickness (≥3.5mm);

For white wine: Observe the transparency (no bubbles or impurities) and test the impact resistance (1.2m drop test without cracking).

Understand the production process details: Ask the manufacturer about the annealing process parameters (temperature, holding time) corresponding to your wine type, mold material and machining accuracy, and raw material proportioning (to ensure no taste migration).

Request batch-specific test reports: Ask for test reports of the batch, including heavy metal leaching (key for high-alcohol liquor), internal pressure resistance (key for sparkling wine), impact resistance, and annealing stress test reports, to ensure that the product meets the safety and quality requirements of your wine type.

6. Why Choose Our Glass Bottles for Bulk Procurement?

Our factory has obvious advantages in all the above factors affecting glass bottle quality:

Advanced technical strength: Equipped with imported full-automatic production lines and a complete quality management system, ensuring the stability of bulk product quality.

High-precision mold manufacturing: Professional mold design and manufacturing team, ensuring the dimensional accuracy and surface quality of glass bottles.

Strict annealing process: Intelligent annealing furnace with precise temperature control, completely eliminating internal stress and reducing cracking risks.

Skilled operator team: Systematic training and strict assessment, ensuring that every link of production is standardized.

Authoritative certification guarantee: All products have passed SGS and LFGB certifications, meeting the safety standards of global markets.

If you are a winery looking for a reliable bulk glass bottle supplier, please contact us. We will provide you with free sample testing, detailed production process introduction and batch test reports, and customize the most suitable glass bottle solutions according to your wine type and procurement volume.

Post time: Nov-16-2025