For wineries that purchase glass bottles in bulk, the cracking or even bursting of wine bottles is not just a matter of product loss—it can lead to damaged wine inventory, increased logistics costs, and even safety risks for workers and consumers. As a professional glass bottle manufacturer with SGS and LFGB certifications, we deeply understand the pain points of wineries in bulk procurement. Today, we will systematically analyze the causes of wine bottle cracking and provide targeted solutions, helping you avoid risks from the source of procurement.

1. Why Do Wine Glass Bottles Crack or Burst?

Before solving the problem, it is crucial to clarify the root causes of wine bottle cracking. For wineries, the cracking of bulk-purchased bottles often occurs during storage, transportation, or even wine filling—these scenarios are closely related to the characteristics of wine products and the quality of glass bottles themselves.

(1) Internal Pressure from Wine Fermentation or Storage

Most wines, especially sparkling wines, white wines, and even some red wines undergoing secondary fermentation, will release carbon dioxide during storage. When sealed in a glass bottle, this gas accumulates over time, increasing the internal pressure of the bottle. If the glass bottle’s pressure-bearing capacity is insufficient, the bottle body (especially the shoulder or bottom, which are stress-concentrated areas) will easily crack. For wineries that store wine for a long time or produce carbonated wines, this risk is even higher.

(2) Defects in Glass Bottle Quality

The quality of glass bottles themselves is the core factor determining their anti-cracking performance—and this is where many unqualified manufacturers cut corners. For example:

- Impure raw materials: If the glass contains impurities such as iron oxide or sodium chloride, it will form weak points in the bottle body, reducing its tensile strength;

- Uneven wall thickness: During the molding process, if the bottle wall (especially the neck and bottom) is too thin or uneven, the pressure will be unevenly distributed when bearing internal or external force, leading to cracking;

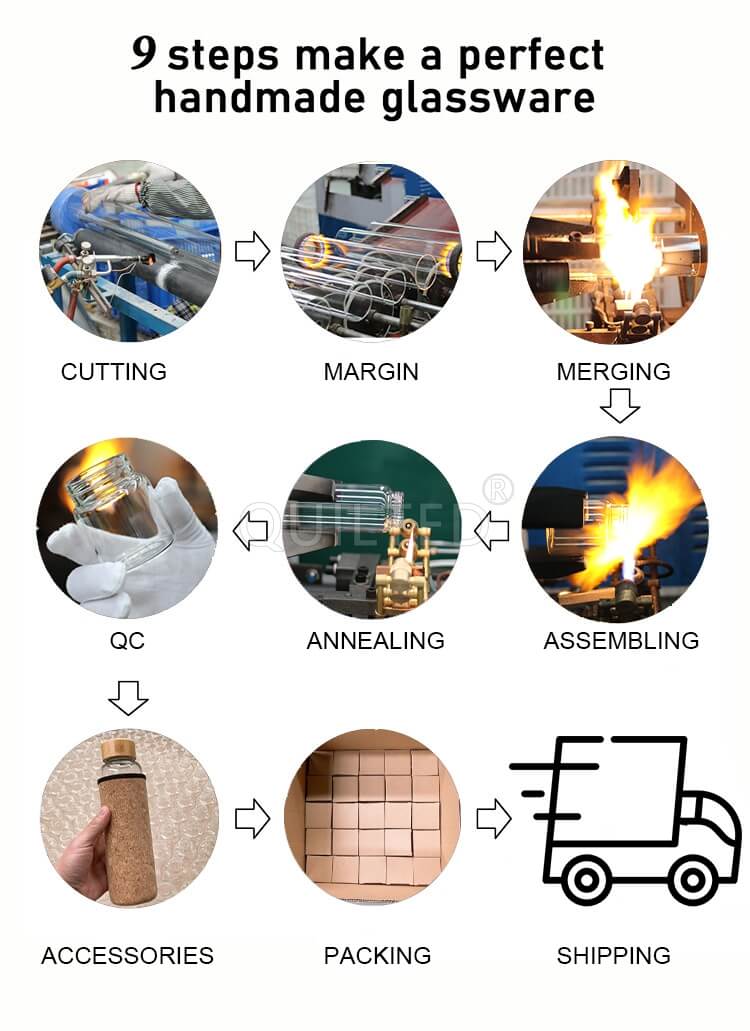

- Incomplete annealing process: After the glass bottle is formed, it needs to go through an annealing process to eliminate internal stress. If the annealing time is too short or the temperature control is improper, the internal stress will remain, and the bottle will crack easily when exposed to temperature changes or slight collisions.

(3) External Environmental Factors

Wineries often face extreme temperature changes during transportation (e.g., from cold warehouses to hot trucks) or storage (e.g., direct sunlight in outdoor yards). Glass is a poor thermal conductor—sudden temperature changes will cause the inner and outer walls of the bottle to expand or contract unevenly, generating thermal stress. When this stress exceeds the glass’s bearing limit, the bottle will crack. In addition, improper stacking during bulk transportation (e.g., excessive pressure on the bottom layer of bottles) can also cause mechanical cracking.

2. Factory-Side Solutions: Solve Cracking from the Source of Production

As a glass bottle manufacturer certified by SGS (international general safety certification) and LFGB (EU food contact material certification), we have established a full-process quality control system to ensure that every batch of bulk wine bottles meets anti-cracking standards. Here are the core measures we take:

(1) High-Quality Raw Materials: Lay the Foundation for Anti-Cracking

We only use high-purity quartz sand (silicon dioxide content ≥99.5%), soda ash, and limestone as raw materials, and strictly screen out impurities through a 3-stage magnetic separation process. This ensures that the glass has uniform density and no internal weak points. Compared with low-quality glass made from recycled waste glass (which often contains impurities), our bottles have a 40% higher tensile strength—this is a key reason why they can withstand higher internal pressure from wine fermentation.

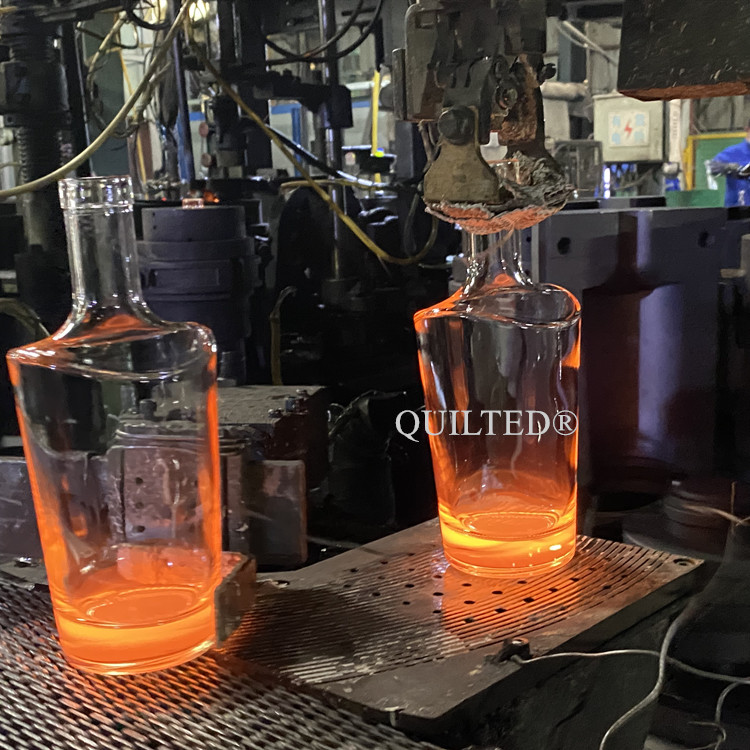

(2) Optimize Molding & Annealing: Eliminate Internal Stress

To solve the problem of uneven wall thickness, we use fully automatic CNC molding equipment (imported from Germany) to control the wall thickness tolerance of each bottle within ±0.1mm—whether it is a standard 750ml red wine bottle or a customized 1.5L magnum bottle, the pressure-bearing capacity of the bottle body is consistent.

After molding, all bottles undergo a 4-hour slow annealing process in a 600℃ intelligent annealing furnace. This process gradually cools the glass from high temperature, eliminating more than 95% of internal stress. We have tested: after annealing, our bottles can withstand a temperature change of 80℃ (e.g., from -10℃ to 70℃) without cracking—far exceeding the industry average of 50℃.

(3) Strict Pressure & Impact Testing: Ensure Bulk Consistency

For wineries purchasing in bulk, “consistency” is as important as “quality”—a single defective bottle in a batch can cause large-scale losses. Therefore, every batch of our bottles must pass two core tests before leaving the factory:

- Internal pressure test: Inject compressed air into the bottle to simulate the pressure of carbon dioxide in wine, and maintain 1.2MPa (equivalent to the pressure of high-end sparkling wine) for 30 seconds—no leakage or deformation is qualified;

- Impact test: Drop a 100g steel ball from a height of 1.2 meters onto the bottle shoulder (the most vulnerable part)—qualified bottles will not crack or only have slight scratches (no penetration).

These tests are not only in line with SGS and LFGB certification standards but also exceed the requirements of most wineries for bulk bottle quality.

3. Winery-Side Suggestions: Reduce Cracking Risks in Use

Even with high-quality anti-cracking bottles, scientific use and storage by wineries can further reduce risks. Here are practical tips we summarize for bulk purchasers:

(1) Avoid Extreme Temperature Changes

When receiving bulk bottles, do not immediately move them from a cold truck to a high-temperature warehouse—leave them in a transition area (temperature 15-25℃) for 2-3 hours to balance the temperature. During storage, keep the warehouse temperature stable (ideally 12-18℃) and avoid direct sunlight (install shading curtains if necessary). For sparkling wine or wines with high carbon dioxide content, avoid storing them in places with large temperature fluctuations (e.g., near air conditioners or heaters).

(2) Standardize Stacking & Transportation

When stacking bulk bottles, do not exceed 8 layers (for 750ml standard bottles)—excessive stacking will increase the pressure on the bottom bottles, leading to mechanical cracking. During transportation, use shock-absorbing pallets (with EPE foam between layers) and fix the pallets with stretch film to prevent collision between bottles. We can also provide customized packaging solutions for wineries’ bulk orders (e.g., anti-collision cardboard dividers) to reduce transportation risks.

(3) Match Bottles to Wine Types

Different wines have different requirements for bottle pressure-bearing capacity. For example, sparkling wine needs bottles with higher pressure resistance (internal pressure ≥1.0MPa), while dry red wine has lower pressure requirements but higher demand for bottle wall thickness (to avoid light oxidation). As a manufacturer that supports bulk customization, we can adjust the bottle design (e.g., thicken the bottom, strengthen the shoulder) according to the type of wine you produce—ensuring that the bottles fully match your product needs.

4. Why Choose Our SGS & LFGB Certified Wine Bottles for Bulk Purchase?

For wineries, bulk procurement of glass bottles is not just a “cost issue” but a “risk control and brand protection issue”. Our advantages lie in:

- Certified safety: SGS certification ensures that our bottles meet international safety standards (no heavy metal precipitation), and LFGB certification allows you to export wines to the EU market without barriers;

- Anti-cracking stability: Through raw material control, process optimization, and strict testing, our bottles have a cracking rate of less than 0.05% in bulk use—far lower than the industry average of 0.5%;

- Bulk customization capability: We can produce 500,000+ bottles per day, support customized bottle shapes, colors, and logos, and deliver bulk orders within 15-20 days—meeting your large-scale production needs;

- One-stop service: In addition to providing bottles, we also offer after-sales technical support (e.g., guidance on bottle storage and use) to help you solve problems throughout the procurement process.

If you are looking for a reliable bulk wine bottle supplier that can solve the cracking problem from the source, please contact us—we will provide you with sample tests and customized solutions based on your wine type and procurement volume.

Post time: Nov-13-2025